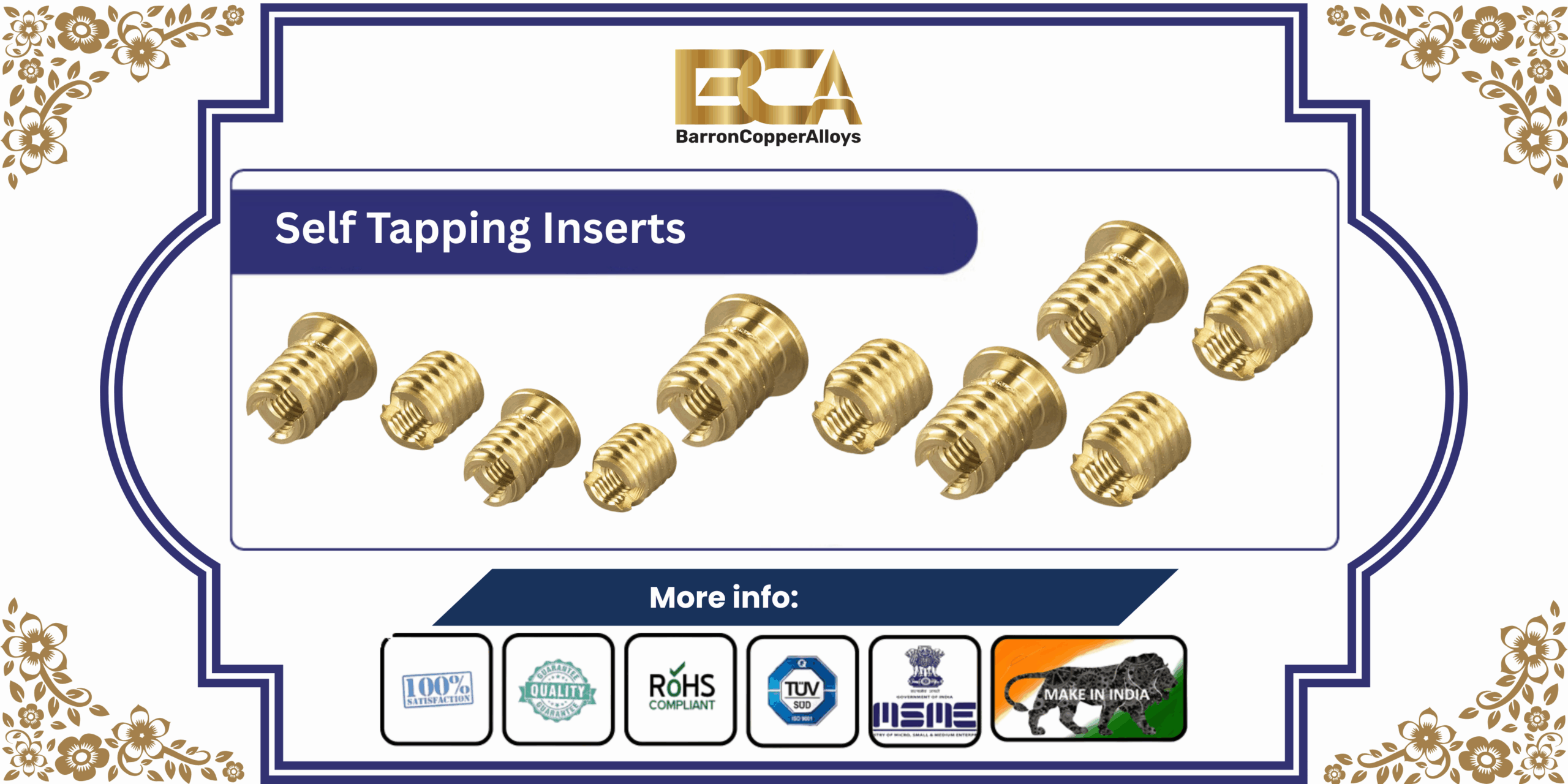

Self Tapping Inserts

- Home

- Self Tapping Inserts

🏗️Self Tapping Inserts – Product Overview

Self Tapping Inserts are threaded metal bushings designed with specially engineered external cutting threads that allow them to tap their own threads into the host material during installation. They provide a strong, durable, and wear-resistant internal thread, ideal for applications where frequent assembly/disassembly or high-strength joints are required.

These inserts are widely used in plastic components, soft metals (aluminum, zinc), hardwood, and composite materials..

Self Tapping Inserts are robust, versatile fastening solutions used to create high-strength internal threads in materials that are otherwise unsuitable for direct threading. Their self-cutting or self-forming external design makes installation quick, reliable, and cost-effective while providing long-term durability.

⚙️ Key Features Self Tapping Inserts

✔ Self-Threading Action

-

External cutting slots or cutting holes remove and displace material as the insert is driven in.

-

Eliminates the need for pre-tapping.

✔ High Pull-Out & Torque Strength

-

Deep, coarse external threads create a solid mechanical grip inside the host material.

-

Offers excellent resistance to vibration and torque-backout.

✔ Durable Internal Threads

-

Internal threads are precision-machined to hold standard screws (Metric / UNC / UNF).

-

Allows repeated assembly without thread wear or stripping.

✔ Easy Installation

-

Installed directly into a drilled hole using a screwdriver, hex driver, mandrel, or installation tool.

-

No special equipment required for most types.

🔩Types of Self Tapping Inserts

1. Slotted Type (Cutting Slot Inserts)

-

Have one or more longitudinal cutting slots.

-

Cuts through the material to form internal mating threads.

-

Ideal for plastics, aluminum, wood.

2. Cutting-Hole Type

-

Cutting holes on the body remove chips during tapping.

-

Used where enhanced chip evacuation is required.

3. Thread-Forming (Non-Cutting) Type

-

Displaces material instead of cutting it.

-

Best for thermoplastics to avoid material cracking.

4. Hex Drive Self-Tapping Inserts

-

Hex socket on top for easy installation with hex key.

-

Suitable for harder materials.

-

self tapping inserts

-

threaded inserts

-

brass self tapping inserts

-

stainless steel self tapping inserts

-

self threading inserts

-

cutting slot inserts

-

thread forming inserts

-

metal threaded inserts

-

inserts for plastics

-

inserts for wood

-

-

inserts for aluminum

-

heavy duty self tapping inserts

-

high strength thread inserts

-

self tapping screw inserts

-

internal threaded inserts

-

metric self tapping inserts

-

UNC self tapping inserts

-

vibration resistant inserts

-

durable thread inserts

-

self tapping insert manufacturers

-

🧱 Material Self-Tapping Inserts

-

Brass

-

Corrosion-resistant

-

Good for plastics, wood, soft aluminum

-

Smooth installation, non-magnetic

Stainless Steel (A2 / AISI 304, AISI 316)

-

High strength

-

Excellent corrosion resistance

-

For harsh environments, metal assemblies, automotive parts

Case-Hardened Steel (Zinc Plated)

-

Very high mechanical strength

-

Good for industrial heavy-load applications

-

How Self-Tapping Inserts Work

-

Drill a pilot hole as per recommended size.

-

Position the insert with the slot end first.

-

Drive the insert using:

-

Hex driver

-

Mandrel tool

-

Bolt + nut tool (DIY method)

-

-

As the insert turns, the external cutting slots tap matching threads into the material.

-

Once seated flush, the insert provides a permanent, wear-resistant internal thread.

Self-Tapping Inserts Applications

-

Automotive components

-

Electronic housings

-

Plastic enclosures

-

3D printed parts

-

Wood furniture

-

Aluminum machined parts

-

Aerospace & instrumentation

-

Repair of stripped or damaged threads

-

High-load, vibration-prone joints

Self-Tapping Inserts Advantages

-

Strong mechanical locking

-

Long-lasting internal threads

-

Prevents stripping in soft materials

-

Excellent for repetitive servicing

-

Improves load distribution

-

Minimizes material cracking (with proper type)

Technical Data Table

| Parameter | Description |

|---|---|

| Internal Thread | Metric / UNC / UNF |

| External Design | Cutting Slot / Cutting Hole / Forming |

| Length Options | Short, Regular, Long |

| Material | Brass / Stainless Steel / Steel |

| Installation | Screw-in / Hex Drive |

| Application | Plastics, Wood, Aluminum, Soft Metals |

Recommended Hole Sizes

(Hole size varies by insert model—example guideline)

| Insert Size | Drill Hole (mm) |

|---|---|

| M3 | 4.1 – 4.5 |

| M4 | 5.1 – 5.5 |

| M5 | 6.8 – 7.2 |

| M6 | 8.0 – 8.5 |

| M8 | 10.5 – 11.0 |

Installation Tips

-

Maintain correct pilot hole diameter for strong grip.

-

Use controlled torque to prevent cracking in plastics.

-

Ensure insert sits flush with the surface.

-

For thermoplastics, thread-forming inserts are safer (avoid cutting).

-

For metals, slotted cutting inserts provide strong engagement.

More Information:

Sample Time:Available in 5-10 days for different items.

Drawing Format:CAD / PDF / DWG / IGS / STEP.

Packaging:Standard package, Carton box or Pallet, As per customized specifications

Shipping:DHL, FEDEX, UPS and By Sea or as per client’s requirements.