Brass Inserts

- Home

- Brass Inserts

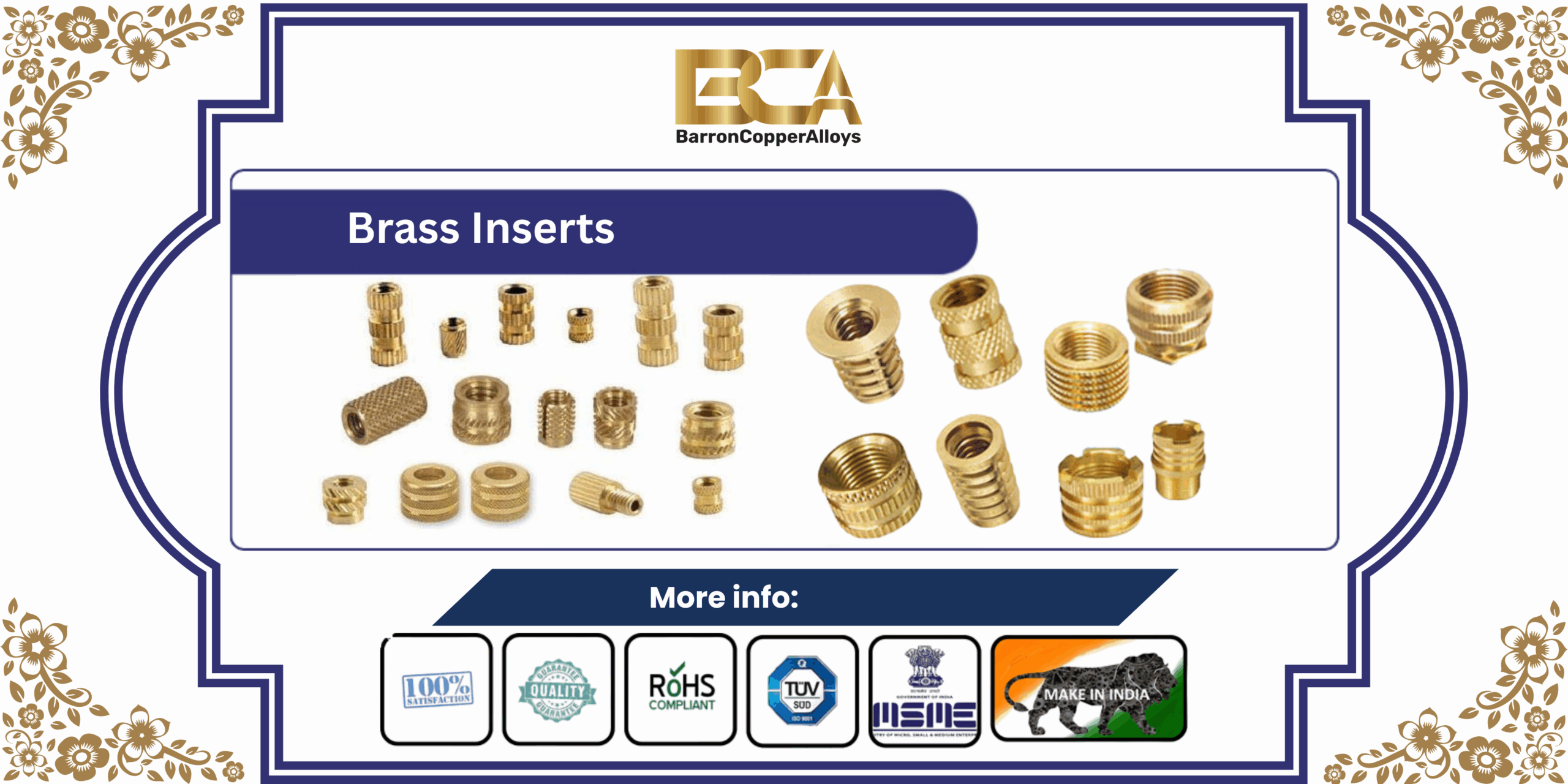

🏗️Brass Inserts – Product Overview

Brass Inserts are precision-machined fastening components designed to provide strong, durable, and reusable threads in plastic, wood, metal alloys, and composite materials.

Manufactured from high-quality brass alloys, these inserts offer excellent mechanical strength, corrosion resistance, and stability under thermal or vibrational loads.

They are widely used in injection moulding, heat-set installations, ultrasonic embedding, press-fit assembly, and wood fastening operations.

⚙️ Material Specifications Brass Inserts

| Property | Specification |

|---|---|

| Base Material | Free Cutting Brass IS 319 Type I / BS 249 / ASTM B16 |

| Optional Material | Lead-Free Brass, CZ121/CZ122, High Copper Alloy |

| Hardness | 65–90 HB |

| Tensile Strength | 350–550 MPa |

| Melting Point | 900–940°C |

| Standards Supported | ISO, DIN, JIS, UNC/UNF |

🔩Design Features

Brass Inserts are available in multiple configurations to suit diverse applications:

-

Helical Knurled Inserts – Maximum grip & torque resistance

-

Straight Knurled Inserts – Balanced pull-out performance

-

Cross/Diamond Knurled Inserts – High rotational locking

-

Press-Fit Inserts – Installed without heat

-

Heat-Set Inserts – Installed through controlled thermal expansion

-

Ultrasonic Inserts – Embedded using ultrasonic vibrations

-

Screw-In (Wood) Inserts – External threads for soft/hardwood

-

Moulding Inserts – Overmoulded during injection moulding

Optional: Flanged inserts, closed-end inserts, long-length inserts, reverse knurling.

-

Brass inserts

-

Brass threaded inserts

-

Brass moulding inserts

-

Brass inserts for plastic

-

Heat-set brass inserts

-

Ultrasonic brass inserts

-

Press-fit brass inserts

-

Brass wood inserts

-

Threaded inserts manufacturer

-

Brass fasteners supplier

-

Injection moulding inserts

-

Brass inserts India

-

Metal inserts for plastics

🧱 Applications Brass Inserts

-

Electrical & electronic housings

-

Automotive & EV components

-

Furniture & woodworking joints

-

Plastic injection moulded parts

-

Consumer appliances

-

Medical instrument enclosures

-

Telecommunication equipment

-

Industrial machinery

🧱Surface Finishes

-

Natural Brass

-

Nickel Plated

-

Tin Plated

-

Chrome Plated

-

Zinc Plated

-

Custom coatings on request

🧱Quality Control & Compliance

-

100% visual & dimensional inspection

-

GO/NO-GO thread gauge testing

-

Knurl profile & depth verification

-

Pull-out & torque mechanical tests

-

RoHS & REACH compliant

-

PPAP / IMDS available for OEM supply

Mechanical Performance

| Parameter | Typical Value |

|---|---|

| Pull-Out Strength | 350–1200 N (material dependent) |

| Torque Resistance | 1.0–6.0 Nm |

| Thread Tolerance | ISO Metric 6H / UNC / UNF |

| Operating Temperature | -20°C to +180°C (continuous) |

Standard Sizes

Metric Threads: M2, M2.5, M3, M4, M5, M6, M8, M10

Imperial Threads: 2-56, 4-40, 6-32, 8-32, 10-24, 1/4-20, etc.

Lengths, outer diameters, and hole size recommendations vary by type (heat-set, ultrasonic, knurled, etc.) and can be provided upon request.

Technical Data Table

| Parameter | Specification | Notes |

|---|---|---|

| Base Material | Free Cutting Brass IS 319 Type I / ASTM B16 / BS 249 | High machinability |

| Optional Materials | Lead-Free Brass, CZ121/CZ122, High Copper Alloy | Export-grade |

| Insert Types | Heat-Set, Ultrasonic, Press-Fit, Moulding, Screw-In (Wood) | For plastic/wood assemblies |

| Body Designs | Helical Knurled, Straight Knurled, Cross Knurled, Diamond Knurled | Optimized grip & torque |

| End Types | Through Thread / Blind (Closed End) | Application-specific |

| Thread Standards | ISO Metric (M), UNC, UNF | Precision-machined |

| Thread Tolerance | ISO 6H / UNC-UNF Class 2B | Consistent fastening |

| Hardness | 65–90 HB | Brass alloy dependent |

| Tensile Strength | 350–550 MPa | Typical |

| Pull-Out Strength | 350–1200 N | Host material dependent |

| Torque Resistance | 1.0–6.0 Nm | Knurl-based |

| Operating Temperature | –20°C to +180°C | Continuous |

| Corrosion Resistance | Excellent (Brass + available plating) | For demanding environments |

| Finish Options | Natural / Nickel / Chrome / Tin Plated | Custom on request |

| Compliance | RoHS, REACH | Safe for global supply |

| Installation Methods | Heat-Set / Ultrasonic / Press-Fit / Moulding / Screw-In | Multi-industry |

| QC Measures | Dimensional check, Thread GO/NO-GO, Pull-out test | 100% inspection available |

Metric Size Chart (M2–M10)

| Thread Size | Outer Diameter (OD) (mm) | Length (mm) | Recommended Hole Diameter (mm) | Installation Types |

|---|---|---|---|---|

| M2 | 3.5 – 4.0 | 3.0 – 5.0 | 3.0 – 3.3 | Heat-Set / Ultrasonic |

| M2.5 | 4.0 – 5.0 | 4.0 – 6.0 | 3.5 – 3.8 | Heat-Set / Press-Fit |

| M3 | 4.5 – 6.0 | 5.0 – 8.0 | 4.0 – 4.5 | All Types |

| M4 | 6.0 – 7.0 | 6.0 – 10.0 | 5.5 – 6.0 | Heat-Set / Press-Fit / Moulding |

| M5 | 7.0 – 8.0 | 8.0 – 12.0 | 6.5 – 7.0 | All Types |

| M6 | 8.0 – 9.5 | 8.0 – 14.0 | 7.5 – 8.2 | All Types |

| M8 | 10.0 – 12.0 | 10.0 – 16.0 | 9.0 – 10.5 | Moulding / Screw-In |

| M10 | 12.0 – 14.0 | 12.0 – 20.0 | 11.0 – 12.5 | Moulding / Screw-In |

More Information:

Sample Time:Available in 5-10 days for different items.

Drawing Format:CAD / PDF / DWG / IGS / STEP.

Packaging:Standard package, Carton box or Pallet, As per customized specifications

Shipping:DHL, FEDEX, UPS and By Sea or as per client’s requirements.