Our Products

- Home

- Our Products

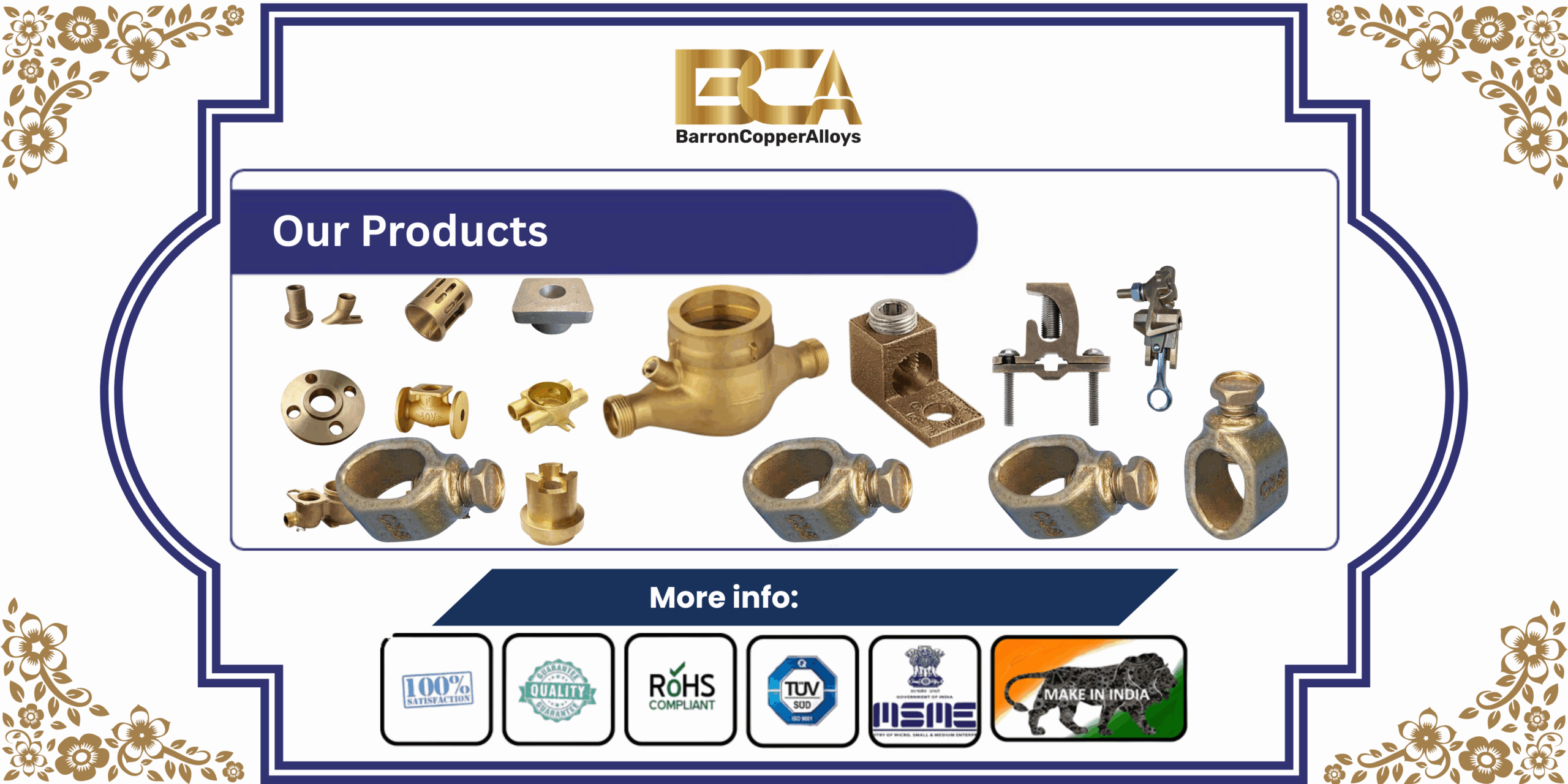

🏭 Our Products – Detailed Overview

Our products are components or finished goods that are made by pouring molten metal (or other materials like plastic, resin, etc.) into a mold, where it solidifies into a desired shape. This process is widely used in industries like automotive, aerospace, construction, plumbing, and electrical fittings.

Common Casting Products

-

Automobile parts: Engine blocks, cylinder heads, brake drums, housings

-

Industrial parts: Valves, pump bodies, impellers, gear blanks

-

Plumbing & Electrical fittings: Brass taps, connectors, couplings, grounding clamps

-

Construction hardware: Manhole covers, pipe fittings, brackets

-

Aerospace parts: Turbine blades, precision aluminum components

-

Consumer goods: Door handles, decorative artifacts, cookware

⚙️ Our Casting Product Range

-

Brass Casting Products – Components for plumbing, electrical fittings, and hardware.

-

Copper Casting Products – High-conductivity parts for electrical and earthing applications.

-

Aluminum Casting Products – Lightweight, corrosion-resistant parts for automotive and engineering.

-

Bronze Casting Products – Wear-resistant and durable parts for heavy-duty applications.

-

Steel Casting Products – High-strength components for industrial machinery and construction.

📊 Applications of Our Casting Products

-

Electrical Industry – Earthing components, connectors, clamps

-

Automotive Sector – Engine parts, brackets, housings

-

Plumbing & Sanitary – Valves, fittings, taps, and meter bodies

-

Construction – Scaffolding clamps, fasteners, supports

-

General Engineering – Precision parts, hardware, and tools

✅ Why Choose Our Products?

-

High Precision – Manufactured using modern casting techniques

-

Material Versatility – Wide range of alloys and metals

-

Durability – Corrosion and wear-resistant design

-

Customization – Tailor-made as per client requirements

-

Global Standards – Manufactured under strict quality norms (ISI, ISO, IEC standards)

More Details:

- Sample Time:Available in 5-10 days for different items.

- Drawing Format:CAD / PDF / DWG / IGS / STEP.

- Packaging:Standard package, Carton box or Pallet, As per customized specifications

- Shipping:DHL, FEDEX, UPS and By Sea or as per client’s requirements.